Live Hash Rosin Process Gallery

The blog team visited the expert Breakwater hash technicians in their on-site lab to document how they transform dry hash into live hash rosin. Check out the process in these photos!

Bulk hash is removed from the freeze drier and quickly carded to check for dryness and inspect for any remaining ice.

Raw ice water extract (hash) is sifted to further check for remaining ice and gently break it down into its granular form. Special pouches are used to refine the hash into rosin, and the sifting process aids in the even filling of these pouches.

The hash technician fills the rosin pouch with hash, making sure to properly pack each bag to yield the highest returns.

The hash technician prepares to press a pouch by getting it situated onto the rosin press plates. The objective is for the rosin to flow off of the plates as quickly as possible. Matching the bag size with the plate size allows the oils to run off and not cook on the plates for longer than it takes to secrete the oils.

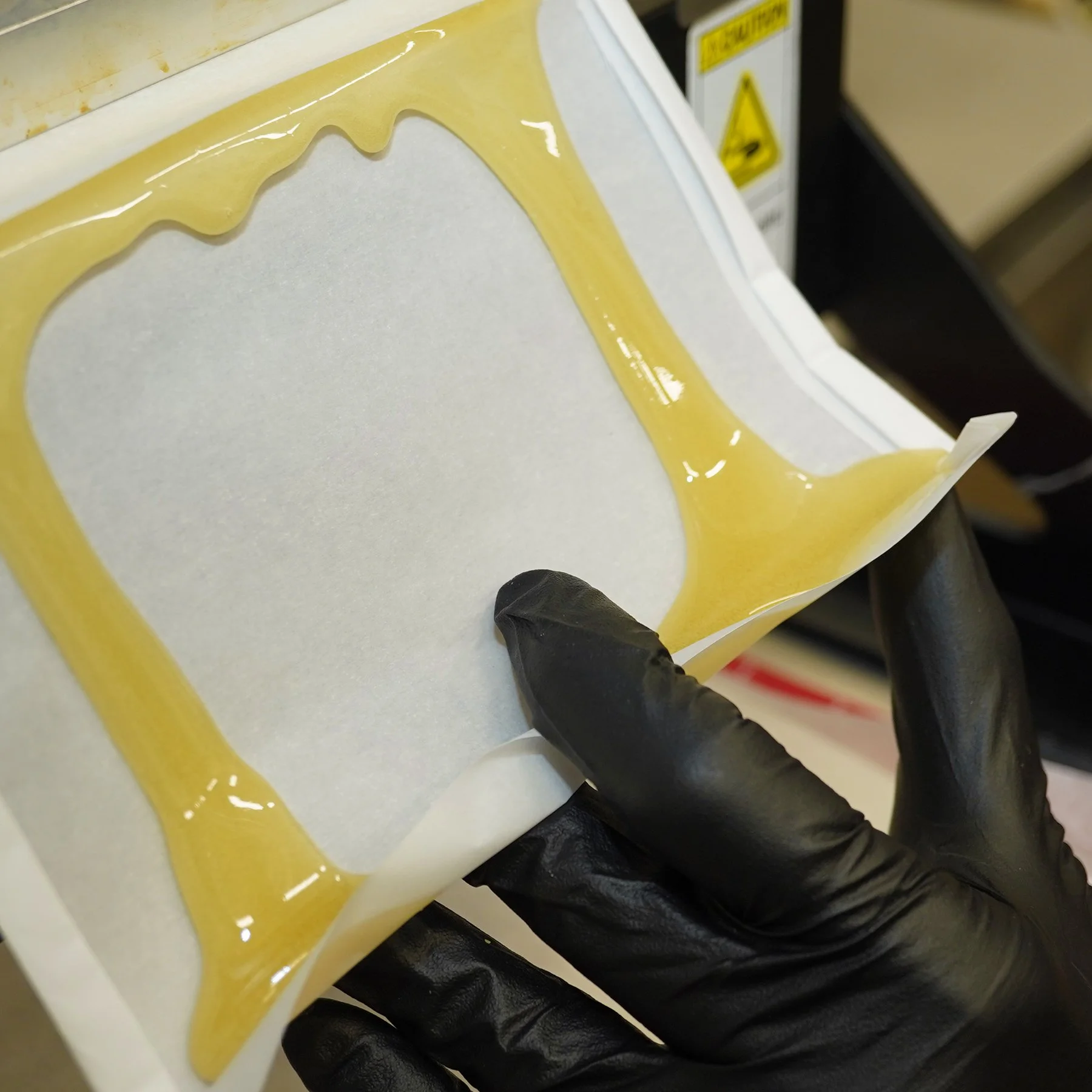

As the hash is warmed and the pressure is increased, the oils are squeezed from the trichome heads and flow out of the bag and onto/into the parchment paper.

For demonstration purposes, the slide shows an “open” press. This just means that once the rosin is pushed off of the plates, it is viewable to the operator (and cameraman) and is not enclosed. This is for the picture only! All of our presses are done between closed sheets of food grade parchment paper to limit oxygen exposure.

A beautiful drip of freshly pressed hash rosin.

After pressing, the pouch is quickly removed from the parchment and then closed again. The rosin is allowed to cool before it is collected. Once cool, each “folder” of parchment containing the hash rosin is stamped on top of each other to create one giant patty to be collected at once.

A close-up of a stack of hash rosin patties.

The final collection of hash rosin is stored in an airtight container and given at least a week (and sometimes upwards of 5 weeks) to cure at room temperature.